Acelen unveils plans to produce renewable diesel, SAF at Mataripe Refinery in Brazil

Mubadala Capital’s Acelen, owner of the Mataripe Refinery in Bahia, Brazil, has signed a memorandum of understanding (MOU) with the state government of Bahia for the production of renewable diesel and sustainable aviation fuel, helping to accelerate Brazil’s energy transition.

Acelen expects to invest more than 12 billion Brazilian reals (USD$2.4 billion) over the next 10 years in the production of renewable fuels.

Throughout the project, the expectation is to produce 1 billion liters (more than 264 million gallons) per year, move 85 billion Brazilian reals in the economy, contribute to the creation of 90,000 direct and indirect jobs and reduce CO2 emissions by up to 80 percent with the replacement of fossil fuel, which will make the company one of the largest producers of renewable fuels in the world.

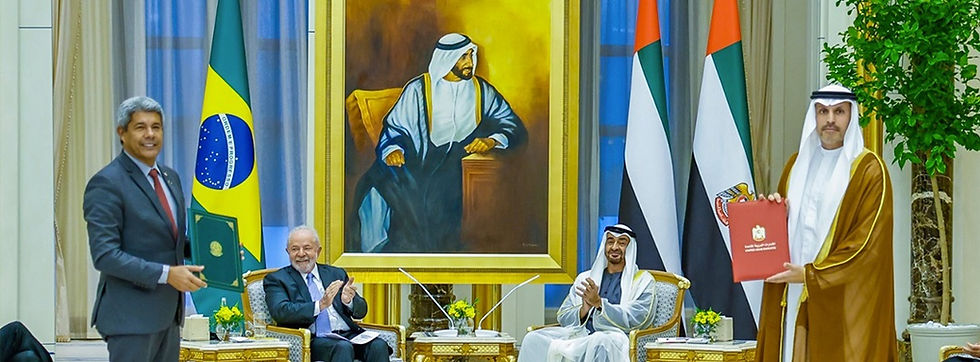

The investment plan and MOU was signed April 15 between the company and the government of Bahia, in Abu Dhabi, UAE, where Mubadala Capital is based.

The company said it will become one of the world leaders in this segment, from the planting of seeds for high-energy agricultural crops to producing renewable diesel and SAF through hydrotreatment of vegetable oils and animal fats.

The company is expected to start production in the first quarter of 2026.

“Acelen’s path towards energy transition began at the beginning of its operations, with the modernization of the Mataripe Refinery and reduction of its environmental impact,” said Luiz de Mendonça, CEO of Acelen. “Now, we are taking a strategic step in our mission to play a leading role in the energy transition in a solid way, with a unique and transformative project, renewing the company’s commitment to a more sustainable future.”

In the first phase of the project, in synergy with Brazil’s agricultural potential, soybean oil and complementary raw materials will be used, which have the largest available volume and competitiveness in the country.

In the second stage, oil from macaúba—a tree native to Brazil with a high energy potential that has not yet been exploited on a commercial scale—and palm oil will be used, with planting expected to start in 2025.

The project plans to plant an area of 200,000 hectares—the equivalent of 280,000 soccer fields—prioritizing degraded land.

The project was structured to have full synergy with the Mataripe Refinery, taking advantage of the existing utilities, tankage and logistics infrastructure.

A sustainable hydrogen-generation unit will be built to hydrotreat the feedstocks.

The plan, according to the company, is to start working on the project as early as January.

The production capacity will be 20,000 barrels per day, or around 264 million gallons per year, equivalent to the annual supply of 1.1 million vehicles, placing Acelen among the largest producers of renewable fuels in the world.

The production of renewable diesel and SAF will initially be aimed at the foreign market, where these products are already approved for sale and consumption.

“We will produce sustainable fuel on a global scale, inserting Brazil in the development of the international sustainable chain,” de Mendonça added. “This will be Acelen’s first project in renewable fuels. So, there is room for us to grow globally in this sector. Our focus will be mainly on the foreign market, initially, producing relevant currency for the country. If Brazil moves forward with discussions already underway regarding incentive policies for the production and consumption of renewable fuels in the country, Acelen will be ready to act in the domestic market as well.”

Acelen will invest in genetics, improvement of agricultural productivity and selection of suitable areas. An industrial-scale seed-germination laboratory will also be created, making investments in research with a series of public and private institutions inside and outside Brazil. In addition to adopting the latest agriculture technology, Acelen said it will develop the oil-extraction process, generating coproducts with high added value and sustainably reusing waste.

-RKstandin.jpg)

_gif.gif)