Harnessing the Potential of Waste Oils

- Tobias Maier

- Jan 15

- 4 min read

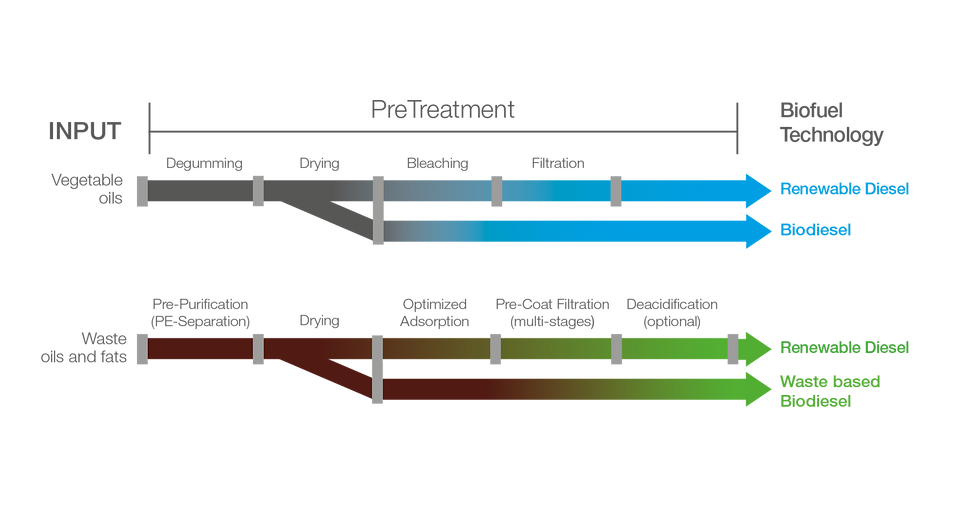

BDI’s innovative, modular and flexible approach to pretreatment offers a promising solution to the challenges of processing waste oils.

In an era where the demand for renewable energy sources is ever-increasing, biofuels such as renewable diesel and sustainable aviation fuel (SAF) are gaining prominence. These fuels, primarily produced from hydrogenated oils and fats (HVO and HEFA), are critical to achieving global sustainability goals.

Producing high-quality biofuels from waste materials, however, presents its own set of challenges. To ensure efficiency and minimize negative impacts in subsequent production steps, strict standards must be met regarding the purity of the feedstock. As such, pretreatment processes become essential—especially when waste oils and fats are involved.

Pioneering Waste-Oil Processing

BDI-BioEnergy International stands at the forefront of tackling the complexities of waste-based oil and fat processing. The company has developed tailored processes and technologies that cater to the unique properties of these raw materials.

Over 27 years, BDI has built an impressive expertise that directly contributes to the efficient production of renewable fuels. The company’s specialized approach to waste-oil treatment ensures not only environmental sustainability but also economic viability for biofuel production.

The Challenge of Waste-Oil Purification

Purifying waste oils and fats is far from straightforward. These materials come with varying degrees of degradation resulting in sticky, difficult-to-process substances.

The contamination levels and composition changes as degradation progresses, making the process more complex. As such, advanced techniques are needed to ensure that waste oils are pretreated effectively for use in biofuel production.

BDI has addressed these challenges head-on by using innovative centrifuge technology.

BDI’s Advanced PreTreatment: The Solution to Waste-Oil Challenges

BDI’s Advanced PreTreatment process offers a robust and reliable solution to the challenge of purifying waste oils and fats. The core of this system is a centrifuge, which helps to prevent fouling and minimizes the need for cleaning, ensuring that the plant runs efficiently with minimal downtime.

The result? A more stable and high-yield process that maximizes productivity while maintaining plant availability.

A Modular Approach for Flexibility, Efficiency

One of the key features of BDI’s Advanced PreTreatment system is its modular design. This approach allows for easy adaptation to various raw materials and product specifications.

Each module is designed to target specific impurities in the raw material, offering flexibility in processing. Whether it’s the PrePurification, drying or adsorption stage, BDI’s modular system can be customized to meet the exact requirements of the feedstock.

Additionally, BDI has developed a process to reduce polyethylene from raw materials—further enhancing the efficiency of the entire system.

The system’s flexibility doesn’t end with the raw materials. BDI’s modular units can also separate or convert free fatty acids, adding yet another layer of versatility to the process.

These capabilities ensure that BDI can deliver a tailor-made solution for every customer, regardless of the complexities posed by the raw material.

Optimizing Plant Operations with Analytical Management

Beyond just the physical technology, BDI emphasizes the importance of flexible plant operation. Its modular system allows for easy adjustments to be made in response to fluctuating feedstock properties. This adaptability is vital in maintaining a consistent product quality, even as feedstock composition changes over time.

BDI goes a step further by providing training for operators to adjust parameters based on analytical results. This proactive approach to plant operation ensures that biofuel production remains efficient and of the highest quality—crucial in an industry where the quality of feedstock can vary greatly.

BDI’s comprehensive support, from raw-material analysis to operational guidance, ensures that its customers are not only equipped with cutting-edge technology but also the expertise needed to maximize its potential.

This holistic approach to waste-oil processing is what sets BDI apart in the competitive biofuel industry.

Conclusion: A Sustainable Future with BDI

The need for renewable energy sources is growing, and biofuels are an essential part of the solution. To meet the global demand for sustainable fuels, however, the challenges of waste-oil processing must be overcome.

BDI’s innovative, modular and flexible approach to waste-oil pretreatment offers a promising path forward. By continuously refining its processes and offering tailored solutions to address specific impurities, BDI is not only advancing biofuel production, but the company is also contributing to a more sustainable and efficient future for the energy industry.

As biofuels continue to play a pivotal role in decarbonizing sectors like transportation and aviation, BDI’s expertise in waste-oil processing is more relevant than ever—ensuring that the biofuels of tomorrow are produced efficiently, economically and sustainably.

Author: Tobias Maier

Associate Division Director

BioFuels & RetroFit

BDI-BioEnergy International

_gif.gif)